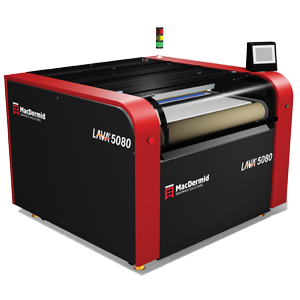

The Right Choice For Quick And Easy Large Format Thermal Plate Processing

The MacDermid LAVA Plate Processing System represents the latest advancement in thermal platemaking technology from MacDermid. Thermal platemaking improves productivity and workflow, generating press-ready plates in less than an hour. Additionally, LAVA Thermal Plate Processing eliminates solvents and VOCs from the platemaking process, resulting in a more environmentally friendly process.

Available in three format sizes, the LAVA Plate Processing System is ideal for narrow web, mid-web, and now, even wide-web applications.

The advanced design of the LAVA system incorporates an internal filter system for reduced footprint, an automated lift lid, and LED illumination.

KEY FEATURES

• Improved productivity and workfl ow; press-ready plates in less than an hour

• Elimination of solvents (VOCs) from the platemaking process

• Smaller equipment footprint than solvent systems

• Updated design for reduced footprint and improved ergonomics

• Available in three format sizes: 25 x 30, 42 x 60 & 50 x 80

TECHNICAL SPECIFICATION

Ventilation

A flexible 4 inch (102mm) diameter, 11 ft (3.4m) long exhaust line is provided to connect with your factory exhaust system.

Plate size

The model number denotes the plate size. For example, the LAVA 2530 processor can process plates up to 25 inches (635mm) wide and 30 inches (762 mm) long. The LAVA 4260 can process plates up to 42 inches (1066 mm) wide and 60 inches (1524 mm) long. The LAVA 5080 can process plates up to 50 inches (1270 mm) wide and 80 inches (2032 mm) long.

LAVA blotter

Blotting material is used to wick away the melted, unexposed polymer. The blotter material is available in three widths: 27, 44 and 54 inches (686, 1118, 1371 mm). Blotter for all three format sizes is supplied in rolls which are 315 yards (288 m) long. Roll weight is approximately 34 lbs (15 kg).