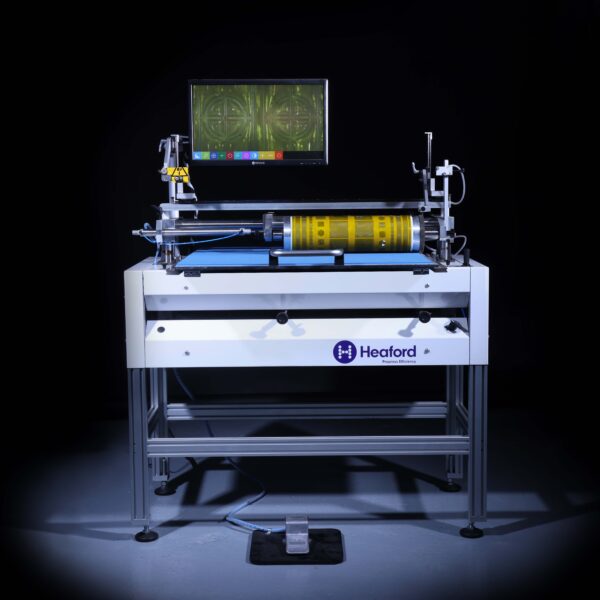

Evo3 All in One

The Evo3 A It is the rst unit of its kind and size equipped with a separate pre-wash section for digital plates with black (LAMS) layer. The 3A is a single pass, in line processor.

EXPOSURE SECTION

• New water circulation cooling bed system

• Uniform and constant temperature without any exposure time limit.

• Vacuum system for analogic plates exposure

• Probe for temperature control

• High concentration of UVA lamps to reach an emission of about 30mw/cm2

• Light integrator

• Lamps air flow cooling system with temperature control

• Optical fibers lamps control

WASHOUT SECTION

• Tilting plate support for user friendly plate loading and un- loading

• Digital washout with separate pre-wash section to prevent contamination of the main washout solvent with black layer

• In-line washout system with front plate entrance and exit

• The new washout system, with brushes’ double movement, allows an extremely fast washout time(from 5 to 10 min. de- pending on plates thickness)

• Servodrive motor advance system to enable a constant and repetible washout speed

• Higher precision solid content analyzer due to new volu- metric pump and sensitive pressure sensor allow a precise % polymer control

• Automatic solvent replenishment system

• Fresh solvent consumption control over the machine life cycle and programmable over a time frame

• Fresh solvent ow regulation option on the touch screen

DRYER SECTION

• 4 sealed drawers to prevent any leak of fumes

• Drying temperature reached in a very reduced time thanks to the new hot air generation and circulation system

• Automatic preheat system

• Automatic switch off option

• Optimal T° uniformity thanks to 2 separate T° controls interfaces

• New air suction system design to ensure a faster plate drying

LIGHT FINISHING SECTION

• Auto combined UVAUVC post exposure (simoultaneous/consecutive/delayed)• Air flow cooling system• Optical fibers lamp control

OTHER FEATURES

• Programmable automatic solvent and dryer warmup

• Automatic standby after the last plate processed

• Remote access (optional)

• Active component visualization during the process

• Manual function to run the components separately

• Memorization of the plate process parameters (up to 24 channels)

Dimensions LxWxH

3000 x 2088 x 1190 (panel 285) mm

118 x 82.2 x 47 (panel 11.2) inches

Power supply

400V 3PH/N/PE 50/60Hz 11kW 17A

230V 3PH/PE 50/60Hz 11kW 29.5A

Plate thickness

Up to 7 mm / 0.276 inch

Solvent

min solvent volume for operation: 90 lts

max solvent volume for operation: 150 lts

max tank volume: x 160 lts

solvent in & out pipes: 2 x 16 mm Ø

Packaging dimensions

3280 x 2260 x 1580 mm

Weight

1440 kg | 3168 pounds

Maximum plate size

90 x 120 cm | 36 x 48 inches

Compressed air supply

min. 7 bar

Exhaust

1 x 100 mm Ø – 200m3/h

1 x 60 mm Ø – 80m3/h

Packaging gross weights

2090 Kg